Our Development

Process

By following this structured process, we ensure that each integrated bearing we develop meets the highest standards of quality, performance, and reliability. Contact us today to discuss your specific requirements and start the development of your custom integrated bearing solution.

-

Initial Inquiry01

Initial Inquiry01Share your technical requirements or project challenges with us. Our dedicated team of application engineers will review your submission and initiate a direct, in-depth contact with you within 24 hours.

-

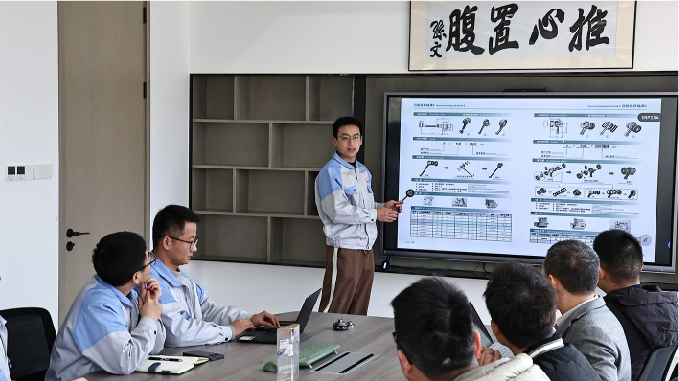

Technical Review 02

Technical Review 02Based on the provided material specifications, we select the most suitable materials that offer optimal performance and longevity for the bearings.

-

Solution & Proposal03

Solution & Proposal03We engineer tailored solutions to deliver peak performance at a fair total cost, ensuring optimal value for your application.

-

Factory Tour & Audit04

Factory Tour & Audit04We invite you to visit our production facilities and quality control centers to witness our manufacturing precision and process rigor firsthand.

-

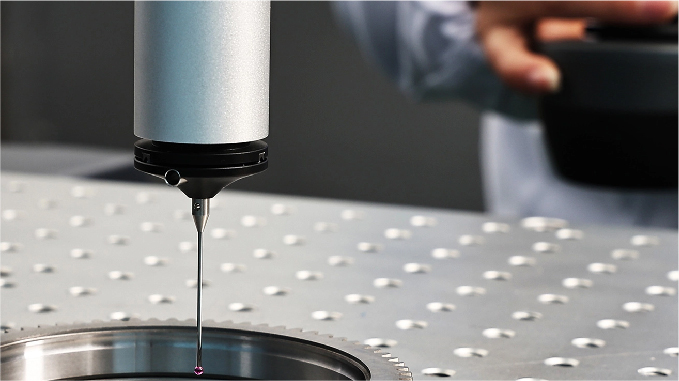

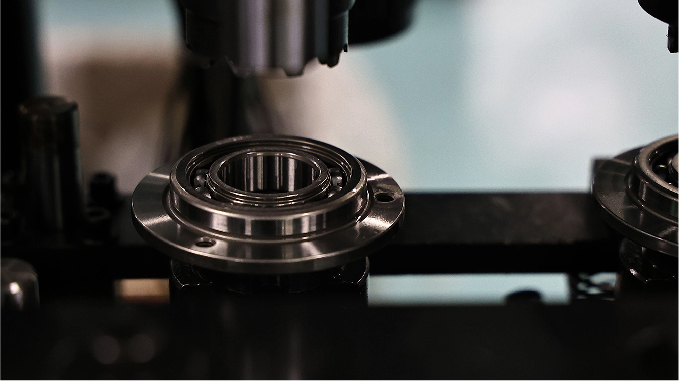

Precision Manufacturing05

Precision Manufacturing05With the final design validated, we proceed to the precision manufacturing phase. Our advanced manufacturing techniques ensure that the bearings are produced to the highest standards of quality and accuracy.

-

Partnership & Support06

Partnership & Support06Each bearing undergoes stringent quality control checks to ensure it meets all specified criteria. This includes checking for correct dimensions, material properties, and performance characteristics.